Looks aren’t everything. After all, beauty is in the eye of the beholder – but at Rotadyne, we understand that you want your product to be durable AND desirable. We make this possible for you by providing a myriad of textures, colours, and finishes. With us, you can let your product’s surface tell your story.

Rotational moulding is extremely versatile in design and aesthetics options. Rotadyne takes full advantage of this, allowing our clients to develop their product and brand identity through colour. Almost any colour can be used, and we can even mix and match to your desired shade, allowing clients to express their individuality and creativity limitlessly. Mixing pigments is often used to achieve decorative effects such as speckling, metallics, granite, stone, translucency, and camouflage. When working with clients from multiple industries, design freedom becomes imperative to accommodate for both practical and visual requirements. At Rotadyne, we value versatility, always aiming to get your product to look the part.

Rotational moulding is extremely versatile in design and aesthetics options. Rotadyne takes full advantage of this, allowing our clients to develop their product and brand identity through colour. Almost any colour can be used, and we can even mix and match to your desired shade, allowing clients to express their individuality and creativity limitlessly. Mixing pigments is often used to achieve decorative effects such as speckling, metallics, granite, stone, translucency, and camouflage. When working with clients from multiple industries, design freedom becomes imperative to accommodate for both practical and visual requirements. At Rotadyne, we value versatility, always aiming to get your product to look the part.

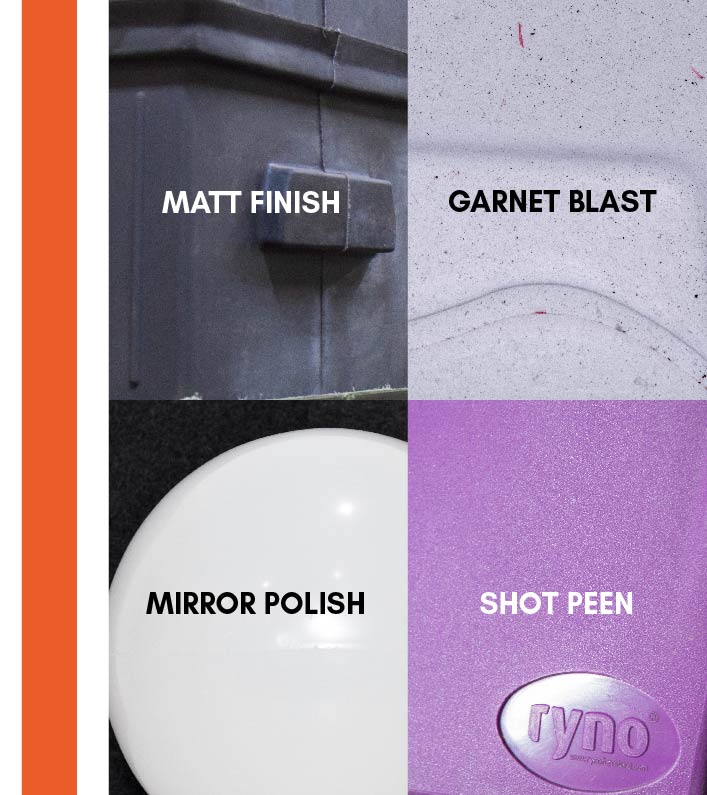

Colour is just the beginning of the visual options Rotadyne offers. Clients are able to take control of their product’s tactile identity with a variety of surface finishing options, each with their respective benefits and characteristics. The most commonly used is shot peening, which produces a rougher texture with dents and dimples. This is most used for products needing to resistance to scratching. It also improves surface defects, notches and any changes to the composition of the piece, allowing for old or damaged pieces to look like new.

Colour is just the beginning of the visual options Rotadyne offers. Clients are able to take control of their product’s tactile identity with a variety of surface finishing options, each with their respective benefits and characteristics. The most commonly used is shot peening, which produces a rougher texture with dents and dimples. This is most used for products needing to resistance to scratching. It also improves surface defects, notches and any changes to the composition of the piece, allowing for old or damaged pieces to look like new.

Another commonly chosen finish is sandblasting, also called abrasive blasting, which produces a textured rustic look. It has many benefits depending on the media used, for example steel shot and grit is tough and highly recyclable, while glass beads and garnet blasting are desired for its smoother, brighter finish. Rotadyne also offers a smooth gloss finish and a smooth matte finish. Rotadyne assures your products’ finish matches its function, helping you make the right choices for your surface.

Tactile identity can further intersect with brand identity through the addition of embossed logos or texts. Not only does this open pathways for interesting and unique aesthetic options for your product, but also provides complete brand identity security with the ability to permanently showcase your business name. Logos and text can also be included in graphics which endure the entire lifetime of the product. This is essential particularly for items which require visible written instructions or safety warnings/directives on the product itself. It also provides the added benefits of flexibility to print on irregular surface textures in high quality with multiple colours without the cost of secondary post-moulding decorative operations.

Tactile identity can further intersect with brand identity through the addition of embossed logos or texts. Not only does this open pathways for interesting and unique aesthetic options for your product, but also provides complete brand identity security with the ability to permanently showcase your business name. Logos and text can also be included in graphics which endure the entire lifetime of the product. This is essential particularly for items which require visible written instructions or safety warnings/directives on the product itself. It also provides the added benefits of flexibility to print on irregular surface textures in high quality with multiple colours without the cost of secondary post-moulding decorative operations.

Mould in graphics are attached to the inner surface of the mould itself before it is cooked and fused into the part during moulding. They are proven durable against chemical exposure, rough use, cracking, and surface oxidation. They are effective on most surface textures including the more aggressive shot peening, however it achieves best results on polished surfaces. Rotadyne also provides the cheaper option of non-permanent graphic vinyls or decals to mark, brand, decorate or label your product as required or desired. However for effective protection from exposure to degrading elements such as the environment, solvents or chemicals, and even the wear and tear of general use, mould-in graphics are the more effective option.

Graphic design Milton Glaser stated, “there are three responses to a piece of design: yes, no, and WOW.” Colour, texture graphics, and other aesthetic details can often be what takes a product from effective to exceptional, giving your product personality and effectively expressing it in the universal language of design.