“You don’t make progress by standing on the sidelines…You make progress by implementing ideas.” – Shirley Chisholm

As concluded in the previous part of the series, changing the world for the better starts with design. The world as we know it was created and then gradually improved by design, and all systems and institutions are built on the foundation of the design and function of their respective products. The design of relevant ‘equipment’ sets the course for the way industries operate, for better and for worst.

This means among us designers and product developers, the goal is usually the same: successfully implementing revolutionary ideas to upgrade the ‘equipment’, so we can achieve industry level innovation and change. This is the case whether we’re looking at interpersonal experiences, such as cleaning our homes, to macroscale activities such as how we vote. Ultimately, when experts collaborate to make these changes happen, the results can be astonishing.

Every Australian soldier involved in active combat operations and target systems over the last decade will have worked with equipment designed and installed by ATS. As they continue to develop their target systems, not only are they securing their position at the forefront of their market, but they are reassessing and modernizing the understanding of what live-fire training means, and what it requires.

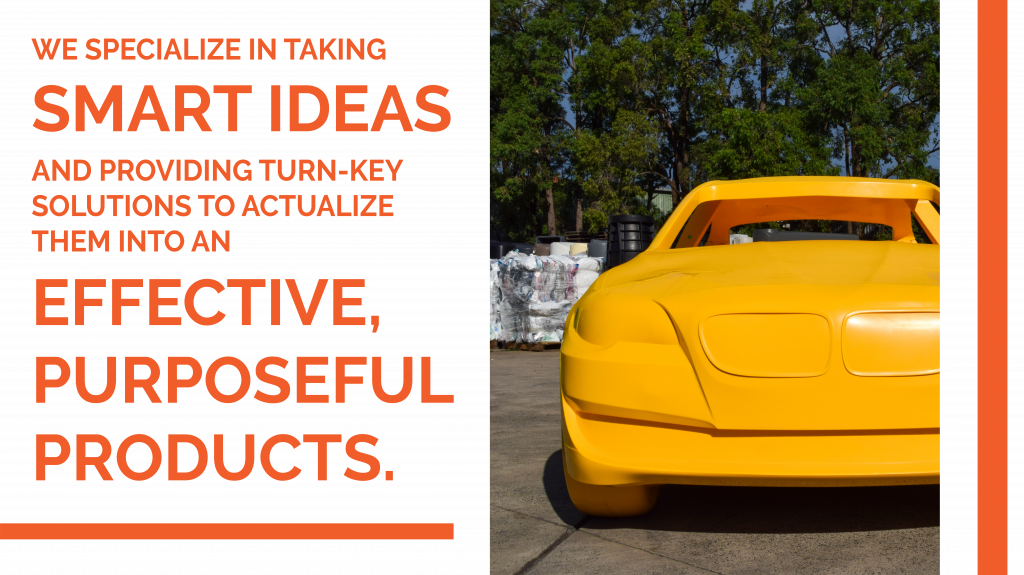

Rotadyne’s contribution is an extensive knowledge and access to various production methods which open the possibilities and imaginations of our clients, giving them opportunities to achieve the once impossible. From rotational moulding to 3D printing, we are a one-stop-shop for the design and production of plastic industrial products with the expertise and experience to help our clients flourish and excel.

Previously, we have covered who ATS are, what they do, and how their collaboration with Rotadyne came to be. Now, from the Rotadyne-ATS collaboration, there are two leading products so far which have been fully realized. For this article, we will take an in-depth look at the opening product: the modular vehicles.

THE PROBLEM

“You can’t solve a problem on the same level that it was created. You have to rise above it to the next level.” –Albert Einstein

Initially, the equipment used were simply re-purposed, second-hand steel cars. There were three predominant issues with them: ricocheting, environmental damage, and weight.

The first is perhaps the most obvious hazard. ATS considers the importance not just correctly using a weapon, but also coordinating fire and movement, and learning to consider concealments, obstacles and covers. Bullets bouncing back and creating “splash back” are a serious hazard for inexperienced trainees who are still learning the ropes and are expected to make mistakes, especially early in their training.

Not only does this limit the realism possible during exercises, but it also reduces the overall efficiency of their education and often leaves participants unprepared when in real-life scenarios.

Not only does this limit the realism possible during exercises, but it also reduces the overall efficiency of their education and often leaves participants unprepared when in real-life scenarios.

The weight of the vehicles was another significant issue. Being able to easily reassemble the equipment into different landscapes is crucial in providing new and distinctive scenarios. which better imitates the diversity in environments and range of unexpected situations they will experience. Weight also becomes a significant logistics complication, particularly when considering an international market demand.

Finally, the original steel cars were startlingly presenting an impending environmental issue: during practice, the cars would often produce oil spills which leak into the ground and surrounding environment. This oil also presented a safety issue due to its flammability. The switch to plastic, despite the stigma behind polymers, actually improves this products overall environmental impact.

THE SOLUTION

“Every once in a while, a new technology, an old problem, and a big idea turn into an innovation.” – Dean Kamen

ATS realized that these issues could be solved by a change in material, and with a specific approach in manufacturing: plastic, and rotational moulding.

Firstly, rotational moulding is the ideal manufacturing method for larger, hollow parts which need to be lightweight, yet strong. It is able to produce parts which are high quality, strong, light weight, and consistent, all characteristics which are essential in this particular project.

The idea is that the change to plastic, which is easily penetrable, can allow for trainees to shoot from, through or around concealment settings without the risk, creating a safe space to build their experience which also better replicates the urban battlefield. Plastic is soft enough that bullets are able to penetrate, but structurally strong enough that it can take the impact of human force. The focus can be directed towards building the trainee’s practical competence, professional capabilities, and accumulative experience, before they’re faced with the front lines.

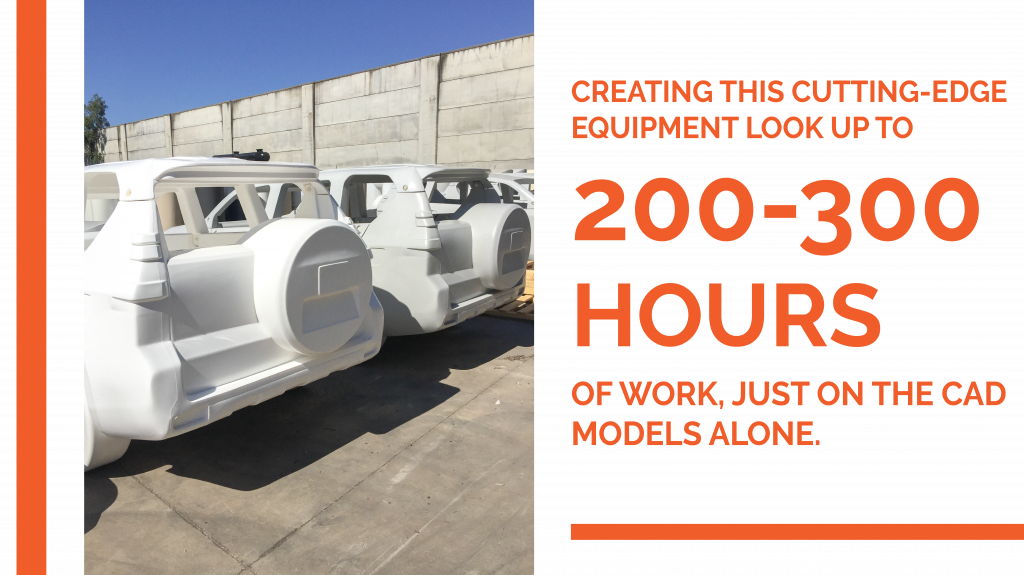

Designing these vehicles to be modular was a process of what our designer Igor called “legofying”. While it needed to be lighter, it also required to have chunky structures that support each other through mechanical fits. The solution was intricately designed teeth-like joints, which secures the individual pieces in place like building blocks, or legos. The modular design is more suitable for packaging, transport and assembly. The final cars are just over 300kgs, made up of 5 interlocking parts, and made of 100% non-ballistic plastic! There is no complicated drilling involved, with only a few plastic screw-in bolts, yet the vehicle still maintains its strength and stability.

Additionally, the plastics used in the equipment are 100% recyclable! Once they’ve expired their training purposes, there’s also the option for them to be reused as parts in a variety of interesting and versatile applications. For example, they could be repurposed for movie sets, artistic projects, or decorative sculptures. Here at Rotadyne HQ, we display one of the original vehicle prototypes at our site’s entrance, honoring this epic collaboration and the values it represents of seeking excellence and innovation.

Finally, Rotadyne provides key production and cost-saving advantages, such as our complimentary ‘Peace of Mind’ service and our ‘Design 2 Manufacture’ processes. These facilitate the process significantly for our clients by taking care of the technicalities, and providing them with professional guidance throughout the entire design and manufacturing process. That means generally, opportunities aren’t missed, and unnecessary mistakes are less often made.

“If we need something rotomoulded, we come to you!” – Kane Mangin, ATS, 2020

THE PROCESS

“Progress is man’s ability to complicate simplicity.” Thor Heyerdahl

This project was a considerable challenge with lots of overlaps and supports to make it work. There was a narrow, defined criteria to meet, as well as specific safety and operative standards. The cars most important features are the connectivity, bolt positioning and perhaps most importantly, its shape, which maintains the products overall integrity and strength.

The first vehicle produced was the Sedan, where the installation was particularly difficult due to the lack of accessibility to inserts and bolts. From this first production, we were able to learn its weaknesses: the interlocking sections were small, weak, and complicated, and we were also struggling to control the bonnet collapses. There was a significant amount of trial and error to perfect this version. Eventually, we were able to prevent the collapses with the addition of supporting welded pipes.

“It was a pretty intense operation.” – Igor Silva, 2021

We used what we learnt from the first rendition to make some significant improvements in the next production, committed to evolve the product further. The SUV vehicle was the second adaption of the modular vehicles, featuring easily accessible, better hidden bolts and interlocking systems which are larger, stronger and more structurally sound. The smaller bonnet also improved the sagging and warpage significantly. The results are an overall superior product, and an indication that as a team, we are on the right track.

The finalized realistic yet safe training equipment allows for a focused and practical approach to combat and target oriented education. Trainees are now granted fit-for-purpose and adaptive training environments which are safe and realistic. Of course, this is not the end of the race for these industry-changing appliances. Future adaptations of the ballistic vehicles are in the works, hopefully aiming to achieve instrumentation technologies such as motion sensors, robotics and communication transceivers.

This project is just one part of the enormous effort to implement realism in live-fire training, which can be flexibly and dynamically applied. The first of many released and upcoming equipment, these vehicles marked the beginning of a project which has revolutionized target training systems as we know it.