MANUFACTURING

Don’t Sail The Storm Alone

You’ve got your design down, now it’s time to start manufacturing it into a tangible reality. However, navigating the waters of product manufacturing can be rough without the insight and experience to guide you across.

The good news?

You’ve got us as your trusted crew.

Versed in a multitude of manufacturing methods, Rotadyne can offer you a range of production pathways, each with their unique strengths, challenges and advantages. We use our decades of experience to guide you through your options, aiming to optimize the process and save you time, costs, waste, and most importantly, stress.

We let your focus remain on your destination, while we tinker with the technicalities for smooth sailing.

Rotational Moulding

Injection Moulding

3D Printing

Post Processing

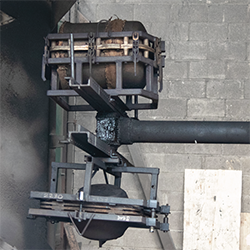

Rotational Moulding

COMPLETE CUSTOMIZATION AND UNMATCHED FLEXIBILITY.

Rotational moulding creates hollow, typically larger products such as water and fuel tanks.

With our custom moulding capabilities, it can be used to create an almost limitless array of products such as outdoor furniture, medical equipment and even vehicle components.

This is because rotational moulding provides complete design freedom with its versatility and flexibility in shape, size, finish, and features.

We have six rotational moulding machines, five which have multiple turret arms, two which are able to mould parts up to 3.6 meters in diameter.

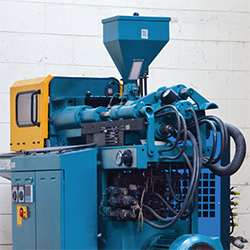

Injection Moulding

DURABLE. UNIFORM. QUALITY.

Injection moulding is popular for its high production outputs and its ability to use multiple materials simultaneously. There are minimal post-production efforts due to its “clean-out-the-mould” characteristic.

It is ideal for smaller parts produced in mass quantity, used frequently to produce items such as medical devices and automobile parts, and bottle caps.

The process involves injecting molten plastic material directly inside a closed mould at high pressure which is then left to cool and solidify.

This happens over the course of 21 seconds and each machine can produce 8-10 hundred parts in a single day.

3D Printing

BENEFIT FROM A CUTTING EDGE TECHNOLOGY.

Additive manufacturing processes involves the layering of material in thin cross-sections to eventually build a completed object.

3D printing is a popular variant of additive manufacturing. It facilitates production of complex shapes and design features, as well as material options suitable for different applications. Rotadyne can help guide you through these production factors.

Applications can include things such as computer and robotics pieces, art, jewellery, and construction components.

Post Processing

READY AND REFINED.

Rotadyne offers post-manufacturing processes such as trimming, polishing, flaming and vacuuming. This service also includes attaching labels, barcoding, and foaming.

The purpose of this stage of production is to perfect each part to a professional, elevated level which distinguishes it as a high quality product. Products also go through multiple quality assessments, such as water tests and pressure tests, to ensure each part meets our production standards.

We can deliver anything from an untrimmed mould, to a completely finished product.

Unleash your creativity.

Our team of designers and engineers are unmatched with their industry expertise and skillful technical know-how.

Learn about our awesome community of clients who have made their mark in their industries and in their markets.

Collaborating with ATS: Delivering Realism in Live Fire Training

“Coming together is a beginning. Staying together is progress. And working together is success.” You have likely heard this quote before, attributed to both Henry Ford (1863-1947) and Edward Everett Hale (1822-1909). It’s about success not just in numbers, but in...

PCA, our Partners in Plastic

Rotadyne may be unmatched in our rotational moulding expertise, but sometimes even we find ourselves out of our element and require a little extra help from external connections. PCA (Pipe Couplings Australia), founded in 1972, initially dealt with the supply and...

Geosentinel Thinks INSIDE the Box for Sustainability

PROJECT DATE: 2018 Rotadyne collaborates with Geosentinel on a portable and effective tooling washout called the WASHBOX, which has grown to become a leading product within the arena of environmentally sustainable design, and a must-have within construction sites....