Rotadyne may be unmatched in our rotational moulding expertise, but sometimes even we find ourselves out of our element and require a little extra help from external connections.

PCA (Pipe Couplings Australia), founded in 1972, initially dealt with the supply and development of pipes, fittings, gas meter values and other gas and oil components. They expanded in 1995 to include manufacturing for customised tooling, injection moulding and extrusion moulding services, which is where Rotadyne sought counsel, and where PCA demonstrated extensive knowledge beyond our expectations, including an unexpected look into the world of 3D printing. We truly all get by with a little help from our friends!

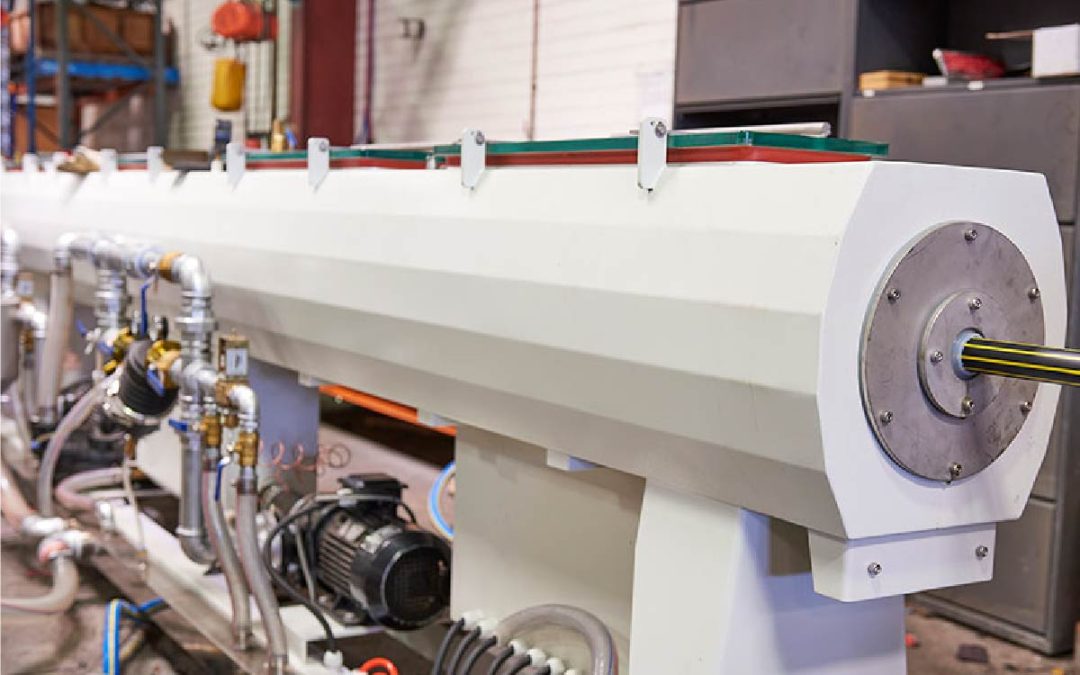

Rotadyne began working with PCA in 2019, with the aim of developing an extruded product capable of joining multiple large panels together. The panels were to be rotationally moulded by Rotadyne, however this process was not suitable for the joiner, leading Rotadyne to reach out to a supplier. PCA’s focus on outstanding product quality and innovation is demonstrated in their continuous funding of ongoing research and development in the plastic moulding arena. This led to them being an obvious choice for this collaboration. Since then, our partnership with PCA has resulted in the successful manufacturing of a unique and innovative product that meets our clients criteria.

Rotadyne began working with PCA in 2019, with the aim of developing an extruded product capable of joining multiple large panels together. The panels were to be rotationally moulded by Rotadyne, however this process was not suitable for the joiner, leading Rotadyne to reach out to a supplier. PCA’s focus on outstanding product quality and innovation is demonstrated in their continuous funding of ongoing research and development in the plastic moulding arena. This led to them being an obvious choice for this collaboration. Since then, our partnership with PCA has resulted in the successful manufacturing of a unique and innovative product that meets our clients criteria.

The collaborative process began with our product development manager, Igor Silva, meeting with Kevin Bailey from PCA to refine and resolve the design of the product. This design was then prototyped both by PCA and by Rotadyne, with machines purchased from PCA, and tested until it was ready for manufacturing. The resulting concept was a complex extruded profile capable of accommodating up to four panels set in 90 degree angles. Rotadyne was warned that this would be a complex tool and part to make, but Kevin walked us through the entire process and helped us with all the critical choices, including the optimal material choice for the end product.

“When Igor first gave me this drawing I thought, oh my god, this is going to be a difficult job… How am I going to thread the material through, and hold it while it cools? Then I had an idea….” Kevin Bailey, PCA

The predominant issue was cooling the product without warpage or damage, particularly regarding threading the material through and it then being held in place during cooling. Kevin found the solution of using removable guides, placed around the joiner in carefully calculated positions. They also used stainless steel moulds which are malleable and relatively easy to adjust.

The joiners are the key part in the products assembly, which meant they need strict sizing and tolerances were of high priority. This process usually involves a lot of trial and error: PCA experts must take into account the maximum metal condition (MMC), or the maximum amount of material used within the tolerance zone. This means the product is made thicker than desired, before being adjusted with carving tools down to its appropriate shape and size. Despite PCA’s concerns with the product’s complexity, they were able to perfect the product after only a couple of tries allowing for the product to be finalised in time to be sent to our customers for their trials and demonstrations.

The joiners are the key part in the products assembly, which meant they need strict sizing and tolerances were of high priority. This process usually involves a lot of trial and error: PCA experts must take into account the maximum metal condition (MMC), or the maximum amount of material used within the tolerance zone. This means the product is made thicker than desired, before being adjusted with carving tools down to its appropriate shape and size. Despite PCA’s concerns with the product’s complexity, they were able to perfect the product after only a couple of tries allowing for the product to be finalised in time to be sent to our customers for their trials and demonstrations.

“Sometimes we need 20 trials…” – Kevin Bailey, PCA

“Other times it comes out pretty quick. That’s the nature of RnD, you can never be sure” – Igor, Rotadyne

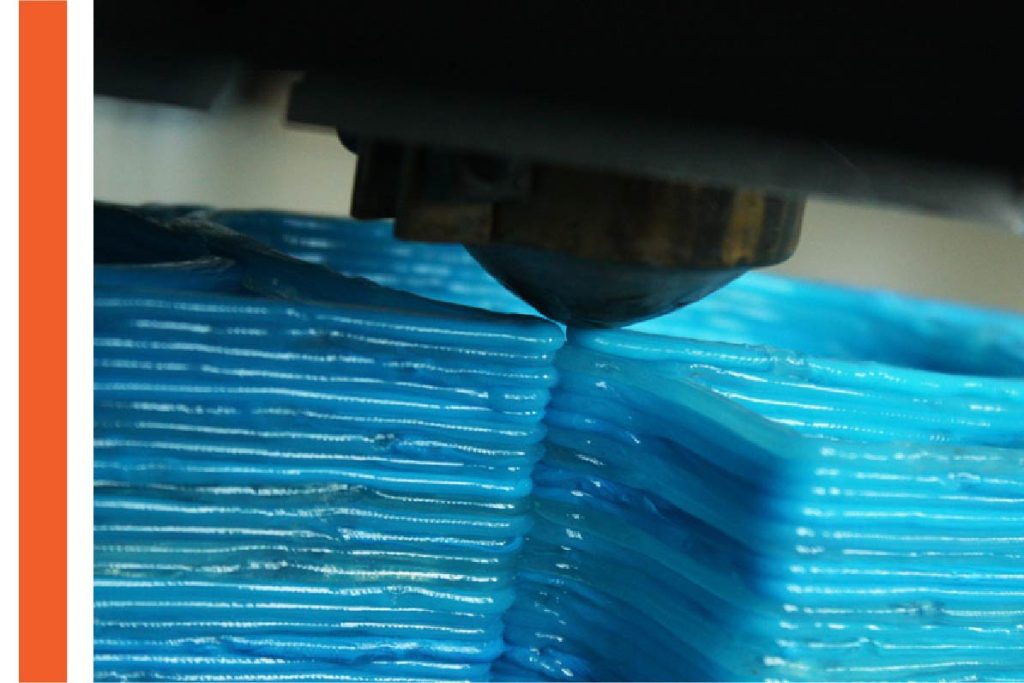

Much of PCA’s services were largely motivated by high demand and limited local Australian availability. This began with gas and oil components, particularly after 1998 with close collaboration with relevant authorities, and now today in 3D printing. It was in Rotadyne’s search for a company from which to purchase a 3D printer that we encountered PCA, attracted to their drive for innovation and evolution.

“With all 3D printing, you need to know what you’re doing…You’re working with something that’s really wobbly, and something that’s not, and trying to make it work.” – Giulio, 2020.

PCA’s Giulio explains how they transitioned into 3D printing services, stating they were searching for something in Australia which was both quality and sizable. Since, they have worked within various industries, printing prototypes and parts used for medicine, home/lifestyle, automobiles, and other fun recreational products. For example, PCA worked with Channel 10 on a carousel in Perth, using 3D printing to create the red decorative ball which perches its top.

PCA’s Giulio explains how they transitioned into 3D printing services, stating they were searching for something in Australia which was both quality and sizable. Since, they have worked within various industries, printing prototypes and parts used for medicine, home/lifestyle, automobiles, and other fun recreational products. For example, PCA worked with Channel 10 on a carousel in Perth, using 3D printing to create the red decorative ball which perches its top.

Rotadyne is also taking its first steps into this growing field, having produced a few 3D printed pieces such as door handles and factory machine parts.

PCA has become a valued supplier to Rotadyne over the past year. We look forward to many more collaborative projects with Giulio, Kevin and the PCA crew, whether it be in the more traditional realm of rotational moulding or in the new found lands of 3D printing services. PCA, thank you for being a friend!